Insert Tooling Solutions for No Lead Brass

The place Peterson Tool Company has within the industry, affords us a unique perspective on the changing playing field from leaded to unleaded brass. The common obstacles that can emerge with almost every project are: chatter, chips, burrs, heat, tool life, part failure and reduced cycle times. It must be pointed out at the beginning of this discussion that there is no “silver bullet” in solving these problems. Each application has required its own idiosyncratic solution however the purpose of this paper is to highlight the treads that are emerging as it relates to inse... read more

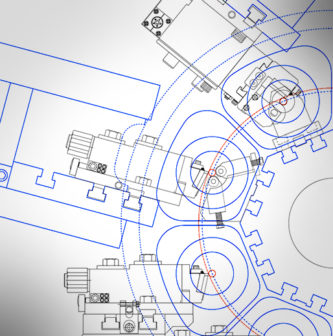

More Parts, Less Maintenance Through Continuous Cycle

Continuous cycle is not revolutionary. In fact, it was probably the predecessor to the high-speed indexing automatic bar machines we know today. Due to the advancements in tooling, specifically carbide, the possibility of new opportunities using old tricks is emerging. The changing dynamics are allowing a shift in the methodology wherein layouts or processes is developed. This shift can open the door for today’s machines to run with more efficiency and less downtime than current constructs allow. How is this possible? The following is a detailed and somewhat technical dis... read more

Ten Points to Consider When Selecting a Tooling Vendor

In this whitepaper we will discuss ten important points to consider when selecting a tooling vendor. Download Now... read more

How to submit a quote

It is our goal to expedite your request for quote as quickly as possible. To help ensure a response that is both timely and accurate, providing the following information at the time you request a quotation will help us achieve our goal and meet your expectations: Include a current legible piece part drawing(s) for the part(s) you want tooling. If you have a group of parts you wish to Thriftchange® we will need a print for all of the parts that are to be included in your part family. Include a current machining layout showing how each part is to be processed. ... read more

Thriftshave Manual

Learn how to fully utilize your ThriftShave® fixture by downloading the ThriftShave® Owner's Manual (PDF).... read more

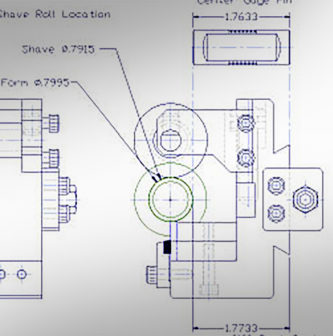

How to set the ThriftShave on Center

In October of 2009, Peterson Tool Company began providing a “Center Gage Pin” with every new ThriftShave design package. This pin has been included to reduce the time required for the initial centering adjustment and to help minimize any setting errors that might occur. Whether this is a single part or a multiple part package, the gage pin should be used to set the ThriftShave fixture on center. If there are several parts to be shaved, only the first part in the package requires setting. Once center has been set no further adjustments are warranted for other parts. T... read more